Power Industry

HC、100Mo、CN、CNS

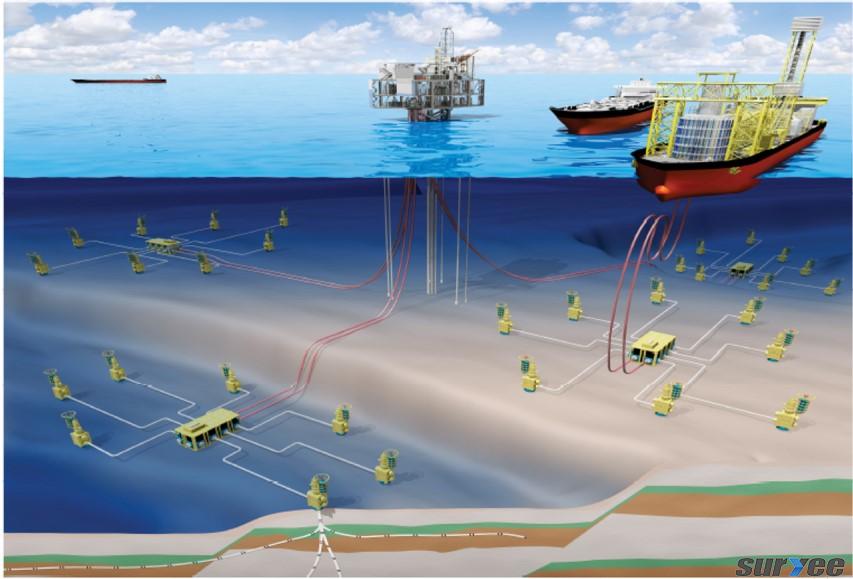

The coal mill is one of the important equipment in thermal power plants, and the grinding roller of the coal mill is a key component of the coal mill. Its quality, especially its wear resistance, directly affects the operating rate of powder production, coal powder quality, grinding roller consumption, and production cost. During the operation of the coal mill, the coal entering between the grinding roller and the grinding disc (cylinder) is crushed under the action of high shear force and high extrusion pressure. The phenomenon of material detachment caused by hard particles during friction belongs to abrasive wear.

The HC, HCM/100Mo (Ni, Nb), and CN-O series self-protection welding powder core wire materials developed by Beijing Saiyi Technology Co., Ltd., including the design of slag and alloy systems, wear resistance, and welding processability, are the best choices for the manufacturing and repair of coal mill roller welding.